Biography of a BMW Motorcycle: Sustainable Life Cycle

We are a product of our context, the social and political landscape we are born into, the resources available to us, and the values held and practiced, both by our immediate world and by our parents. We are shaped by the acceptance (or not), the expectations (or not), of others. They have designs for us with intentions in mind before we come to be; the better ones also give space to let our unique selves and qualities emerge.

All of those things together are part of our biography as well as the biography of our motorcycle and the stories of places we ride and explore on them.

My motorcycle and I are most at home out in nature. Taking photos of my BMW G 650 GS, amongst natural formations and foliage little touched yet not too far down from the visible, large-scale natural resource extraction – I think about my place in all of it, my motorcycle’s place – how are we part of both processes.

I have a sense of my own place in all of this, but was less sure of my motorcycle’s, so I sought to examine my motorcycle’s biography through the lens of BMW Motorrad’s and BMW Group’s operations and sustainability practices, by tracing as much as I could of the life cycle of a BMW motorcycle. This is what I found.

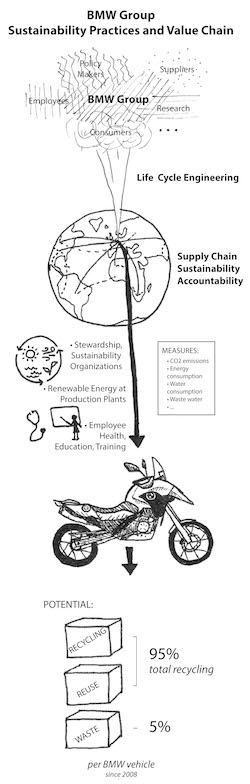

The environment in which BMW Group currently exists very much influences its design of vehicles, materials used, and the supply chain. There’s the motorcycle market in general, laws and regulations that need to be complied with, as well as consumer’s interests, demands, and expectations. The company views its stakeholders as everyone – even the research community, employees, non-governmental organizations (NGOs), local stakeholders, and the larger civil society. Increasingly, there is pressure on all sides for environmentally and holistically sustainable business and production practices and products.

BMW Group states, “Climate change is one of the greatest challenges facing society today” and “we comply both with stricter legislation worldwide and our customers’ increasing awareness of environmental issues.” BMW Group sees customers’ expectations of sustainability as especially important to meet because of industry competition. Integral in its core values are sustainability and responsibility, which BMW Group sees as good business sense. I had the opportunity to interview Kai Zöbelein of BMW’s Sustainability Communications, who said, “Sustainability is part of our strategy and part of our corporate identity. We are convinced that acting sustainable is important to generate profitability.” BMW Group does not see these changes as a cost, but as a value and as being ahead and even leading the industry.

These values, then, are what my motorcycle came out of when it was born in 2011. The values influence design, materials, the supply chain, production, and end-of-life considerations. The most critical point for this long-term view is the Life Cycle Engineering, the front-end development phase, to ensure “sustainability throughout the entire life cycle.” For urban-oriented vehicles, such as the BMW C evolution, electromobility with zero emissions is an emphasis of BMW Motorrad and BMW Group, though it is acknowledged that important to this equation is that the vehicles are charged on a green electricity infrastructure, and so BMW Group invests in different ways to spur innovation and help places throughout the world move towards such an infrastructure. Integrated into all of this is a “Design for Recycling,” which allows parts to be recycled throughout a motorcycle’s life and end-of-life, which reduces carbon dioxide emissions in the larger picture.

Another large part is where our motorcycles have come from. It’s always fascinating to trace our own roots across the world, so what about the materials that make up my motorcycle – from their extraction, processing, and the suppliers? While it would be a bit too complex to wade through BMW Group’s 13,000 suppliers across 70 countries to those specific to BMW Motorrad operations and my motorcycle in particular, what I did find out about are more on the standards BMW Group holds itself to, in turn holds its suppliers to, and its expectations that suppliers hold their suppliers to the same.

In effect, BMW Group is using its powerful position to influence the progress, sustainability, and responsibility of the supply network it is connected to across the globe. Impressively, BMW Group looks at itself critically and measures and publishes publicly the numbers of its own environmental impact, whether trending towards and meeting its goals or not. The breadth and specificity of what is measured really reflects the seriousness and holistic way in which the company is defining sustainability and its responsibility, with indicators such as water consumption; waste water; waste (recovered/recycled versus disposed); energy consumption (production plants, corporate functions, fuel types); and CO2 emissions, whether direct from production, company vehicles and company-owned planes, or indirect such as from business trips and employees’ commutes.

Emissions from the supply chain are often greater than BMW Group’s own, and so companies wanting to be suppliers to BMW Group must comply with environmental, social, labor, and human rights responsibility standards drawn from international standards such as those from the UN. BMW Group examines, and wants its suppliers to examine, the full supply chain of their raw materials and especially potential conflict minerals to ensure that at no point are human rights being violated or conflicts funded by those raw materials used in BMW vehicles.

BMW Group expects suppliers to report on certain environmental indicators (CO2 emissions, energy consumption, waste water, etc.) to increase transparency and ensure compliance, and is itself even part of raw material sustainability organizations, such as the Aluminum Stewardship Initiative, of which BMW Group was a founding member. If suppliers are found short of meeting BMW’s standards, BMW will work with them, share its own best practices, and outline corrective measures with dates by which the supplier must meet them. Termination of the business contract is seen as a last resort, as BMW prefers to build relationships and work with suppliers to meet the standards. To provide transparency, BMW Group publishes the aggregate information of gaps and successful corrective action publicly, as well as notes situations in which the Supply Chain Response Team investigates potential human rights violations.

For me, being conscientious in my own daily life to live as ethically and responsibly towards others and in my impact on the environment as possible – I find it reassuring to know my companion, my G 650 GS, is doing the same. From the materials that makes its parts, through its production, where BMW not only reports on environmental impact measures of production, but is transforming the energy sources of its plants to be cleaner, renewable energy, whether wind turbines, solar, or even biogas.

After living a hopefully nice, long, fulfilling experience, we humans and our motorcycles come to the end-of-life conversation to varying degrees. Unless we donate our organs to the living or our body to science, our physical self does not carry on or contribute much to the tactile world thereafter. Our BMW motorcycles – especially the newer ones – will.

I asked Kai Zöbelein about the post-life of BMW motorcycles and parts. He said that “all BMW Group vehicles brought onto the market since 2008 meet the strictest global requirements set for the recycling of end-of-life vehicles, components and materials, [which is] 95 percent total recycling, 85 percent reuse and material recycling.” To me, those numbers are remarkable and show what really is possible with thoughtful and strategic engineering. There is also the question of whether systems are in place for collecting, recycling and reusing the materials and components, which is in some ways the more difficult part as it is out of BMW Group’s control. At this point, there is no required training on the recycle or recovery protocol for used parts and end-of-life vehicles for BMW motorcycle dealerships and service department employees. Also, most recycling is done by privately-owned companies and not BMW. BMW does have online information and instructions on vehicle recycling, however.

The family one grows up in, and its dynamics, also influences one’s character and outcome. BMW Group gives attention to the performance and health of employees through different company initiatives. Diversity – age, gender, culture – is valued and seen as a source of the company’s innovation and competitive edge. BMW examines salaries annually to ensure gender-neutral compensation, and invests in training and education for employees because it finds this important to developing its employees for the value such investment brings to the company. There is also flexibility where possible for different work-life balance arrangements.

As I examined the environment and delved more into my motorcycle’s family and biography, I came to better understand its place in the world and the complexities that are part of its existence. I appreciate even more the detailed attention and values of BMW Group and the work done behind the scenes. I know change, for people and for organizations, can be daunting. Interestingly, however, as I read how BMW Group describes itself and Kai Zöbelein’s account, I do not sense that BMW Group saw this focus on sustainability as a change or a cost, but rather as progress and value, and becoming the identity it saw itself as, and wanted to be seen as. I asked Kai Zöbelein about this, and how other companies may be hesitant to move towards a more sustainable business environmentally, socially, along employee development and health. He said, “From our point of view, every company needs to decide this itself.”

BMW has certainly shown it is possible. Now as I ride and explore the world, I am assured that there are groups and organizations working to keep these places, communities, and relationships viable for future generations of riders, and know that I am doing my part, too.

Much appreciation and thanks to Kai Zöbelein with BMW Group in Munich and Eric Valtos with BMW North America, for their help in the research and information of this article.

Further information and citations from:

- https://www.bmwgroup.com/en/responsibility.html

- https://www.bmwgroup.com/en/responsibility/sustainable-value-report.html

- https://www.bmwgroup.com/en/responsibility/supply-chain-management.html

- https://www.bmwgroup.com/content/dam/bmw-group-websites/bmwgroup_com/company/downloads/en/2009/2009_Vehicle_Recycling_Focusing_on_Sustainability.pdf